Nike - Company Profile

Question:

Analyse the case study of Nike "ERP system failure".

The systems of ERP are information system backbones and they reach within every business areas and supply chain to enhance its values. The integration offered by ERP is for all the operations and functions in a company to be conjoined to form an individual device system with an aim of serving specific needs of everybody (Amoako-Gympah 2010). The presence of ERP systems helps in exchanging information and facilitating communication between every organization department. Every module has an individual way of working and leads towards performing particular functions of data-processing.

When ES is implemented in a successful manner, it leads towards linking every area in a company inclusive of managing order, human resources, manufacturing process, external supplier’s distribution and also consumers into a tight systematic integration wherein data is shared and visible. A research survey from AMR took place between 110 companies with a yearly revenue of 500 US million dollars with the help from ERP (Amoako-Gympah 2010). The survey revealed that there are various organizations which have failed in successfully implementing ERP systems such as Nike. It was acknowledged by the analysts that indeed a bold step was taken by Nike when an individual strategic instance was adopted with the initial rollout of ERP.

This report acknowledges the reasons for ERP system implementation failure and problems in the supply chain of Nike which led to this failure. This report also offers recommendations in order to help other organizations with similar nature to understand the lessons learnt from this failure (Amoako-Gympah 2010).

Are You Daunted by the Thought of due Case Study ?

Avail Our Services and Receive Case study Help from experts.

Nike, was founded in the year 1957 by Knight and the company since the very beginning manufacturing higher quality sports shoes for several sports inclusive of athletics, football, volleyball etc. Additionally, the company also has been involved in manufacturing equipment’s for fitness and related sports apparels such as caps (Amoako-Gympah 2010). The organization since its development has always been involved in making higher commitments to innovative products. In the fiscal year of 2012, 24.1 billion dollars was generated by Nike with an increase by 16 percent since the last year. The organization further made announcements of increasing this total revenue generated in the 2015 fiscal year to reach 30 billion. More than 50000 employees across the globe are employed by Nike and there are several contracts wherein the company employs more than 80000 individuals. The mission statement of Nike is to develop inspiration and to consistently innovate for each sports person across the globe.

In the year 2000, however Nike took the decision of implementing a unique management of supply chain with the ability to forecast demand in the market so that the company can quickly meet with these requirements. This was also the time when the organization also was in the SAP ERP system implementation process but the company found that the forecasted demand was not adequate to the requirements at that particular situation (Amoako-Gympah 2010). This made the company to adopt and choose the software named as I2 in order to enable the organization to quickly respond to the changes in the market of shoes, scheduled of planned productions with newer requirements and start to produce new products within a week instead of waiting for a whole month as the company did before. However, if successful then this strategy could have been a very fruitful one for Nike and the company would have been easily able to decrease the unwanted products from being produced, decreased inventory system and increase the shoe styles production rising the required demand. It was also known to Nike that implementing ERP systems can be very threatening and so the company was very patient when implementing these systems but as the system of I2 was very small, various precautions required to be taken by Nike were not taken.

ERP implementation at Nike

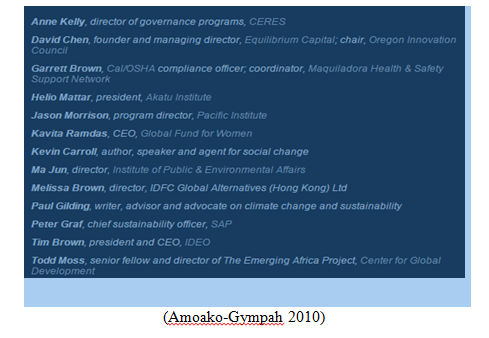

The above mentioned stakeholders list are the 14 important stakeholders involved in the process.

The particular demand planning software instance is known as the software of I2 which was the main factor that led towards major problems in the company. The company of Nike failed in properly evaluating the way in which this new software of planning demand will be integrated within the system legacy (Amoako-Gympah 2010). The company rushed in implementing the software prior to their main package of SAP which was not ready to be deployed causing the system failure of I2 within the supply chain of Nike. There is no doubt that the company had a unique process of supply chain which needed the stores to make merchandizing pre-orders that is in advance for 6 months. The issue in this was the fact that the company did not every know whether the ordered sneakers in Nike’s store will be fashionable in the next 9 months when the same will be delivered to the stores. The company’s fashion designers and the planners of demand did not acutely interpret the way in which order with such a high leading time should be placed and the company totally depended on the brand name of Nike for selling its new products. In the shoe market a short order shipment of products is always demanded from the stores and this forced Nike to be under competitive pressure for getting their system of supply to perform in the next 6 months. The challenge of not being able to get the SCM in position led towards opening the company to lose out on the share in the market especially because of the fierce market competency (Amoako-Gympah 2010). Therefore, when I2 system was implemented at Nike and the system lost the capability of holding up urgent and vigorous requirements of the9 month cycle planning, the company began to lose out and the forecasted information also completely was thrown off resulting in making the supply chain to cost the company 100 million dollars from damages directly. The company also had to face brand image problems, law suites being filed on its name and other speculative investigations further lowering the reputation of the company.

The software of I2 was actually made to help Nike in matching the demand and supply by mapping the specific products to be manufactured. The software needed to be linked with several ERP systems and back end processes (Amoako-Gympah 2010). This project also was a replacement from the previous Manugistics implementation. The responsibility of the new project was to reduce the rubber needed, canvas needed and other sports requirements to be fulfilled by Nike but it failed.

- The new system of I2 needed customization to this legacy applicable at that speculative period. In addition, the big bang approach tried by Nike to implement the new system of managing the supply chain resulting in deteriorating the status of the company.

- The engine of demand-planning in the year 2000, named as I2, of the company, Nike, established order for several Air Garnetts rather than the demand of the market and for several popular products.

- There is no doubt that the company had a unique process of supply chain which needed the stores to make merchandizing pre-orders that is in advance for 6 months (Amoako-Gympah 2010)

- The issue in this was the fact that the company did not every know whether the ordered sneakers in Nike’s store will be fashionable in the next 9 months when the same will be delivered to the stores.

- The company’s fashion designers and the planners of demand did not acutely interpret the way in which order with such a high leading time should be placed and the company totally depended on the brand name of Nike for selling its new products.

- In the shoe market a short order shipment of products is always demanded from the stores and this forced Nike to be under competitive pressure for getting their system of supply to perform in the next 6 months.

- The challenge of not being able to get the SCM in position led towards opening the company to lose out on the share in the market especially because of the fierce market competency.

- This resulting in causing a loss of 100 million dollars sales and this depressed the price of stock by 20 percent. In turn this resulted in various lawsuits of class-action nature after which Nike stated that this new system will gave the responsibility to manufacture the sport shoes of wrong kind (Koch 2004). Nike however failed in properly training the employees in understanding the function of the new system leading towards excessive creation of products which were wrong. This was a main destruction faced by the company especially when the company had already invested more than 400 dollars (millions) over the process of implementing this software.

- This was the main blow to the company especially when the system implied that it has gone slow, there is no integration and there are various bugs in the system.

- Massive losses were faced by Nike and issues of large technical nature were faced by the company and all were related to the fact that the software failed to properly function.

- Consultants were brought in for building database and for bypassing the I2 application portions.

- The company further built bridges inside the software for enabling information sharing. This caused Nike to switch ranges of short and medium planning of sneakers to the system of SAP ERP which was using more estimated demand predictive algorithms.

- This also made the company to find a new foundation for the system of SCM and the company started to focus on training its employees for approximately 140 to 180 hours in order to make them perfectly understand the working of the system (Kalin 2002).

- Furthermore, a phased geographical process was implemented when the new SCM implementation and CRM along with ERP system implementation failed. This program was envisioned as an implementation of 2 to 3 years but the company took almost 6 years investing further more than 500 million dollars for properly implementing the system of supply chain to be managed.

The implementation of ERP, CRM and SCM systems at the same time and all together made Nike to experience benefits in multitude. These advantages were linked with the system of I2 management resulting in a better collaborative aspect with the factories of Nike in the far eastern area. This in turn resulted in reducing the pre building time amount needed for every shoe to be manufactured. The reduction was by 40 percent to approximately 4 percent. This time amount from the start and till the completion of the shoe was lowered by 6 to 9 months which led towards faster cycle time of product to market (Laudon et al 2010). The levels of Inventory were decreased from cutting the time of interval from a month to a week. This system helped in better demanding forecast and demanding visible aspects. A reduction in the experience risk led towards the effect of bull whip. In the end, the main reduction of cost took place by reducing the inventory process, costs of process and costs of product to increase the marginal gross value. Even though the experience of Nike was highly problematic in nature, the SCM implementation system still advantaged the company and offered it various benefits in the new system leading towards offering the company to enhance its revenue projections, the rate of productivity and also the sales of the company. The problems by Nike were solved by switching the vendor software’s. Currently Nike is making use of LLamasoft from the requirements of their ERP. There was clearly no breakage in the implementation of I2 technologies at Nike (McLaren et al 2005). The requirements, obviously from the side of the client were not satisfactory and this resulted in the requirement of line of communication to be even more previse and highly frequent in nature. Nike’s ERP system implementation of I2 technologies therefore was not a failure but it was just an experiment which the company took in its hands in order to understand the other ways by which the company will succeed in long term.

The I2 Software - Main Cause of Failure

Therefore the management at Nike was not a failure but a journey from failing to succeeding even though it makes the company lose out on time or capital (Laudon 2007). The recommendation offered will be on the important factors of success being managed which are inclusive of startup of project, committing management, scope of the project being outlined, team of project is established, managing change, communicating the change, training employees, customizing and modifying, budgeting and closure of the project. In the initial stage that is at the startup of the project, it is recommended that the company should develop a strategy for business, reviewing the strategy of IT, strategy of ERP, scope of the project, preparing the company to change process and application of the new system in accordance to the strategies of change management. At the second stage, commitment to management, the implementation recommended will be inclusive of involving all the stakeholders in the sponsorship of the project which are also consisted of committee of steering, escalation of issue and resolution of issue. This will further help in maintaining the support of management keeping them informed over the project (McVey 2001). The third stage is the scope of the project where it would be recommended that the company first understands the requirements of the business and then plan the way in which the requirements can be satisfied rather than simply moving towards implementation. The project team on the other hand should apply proven methodologies of implementation and project tools that can empower the decisions made by the team in the implementation process.

Conclusion

From the perspective of analyzing the case of Nike, it was evident that the exploration of implementing ERP done by organizations needs to consider the important factors of success and then recommendation should be provided to maintain success with the implementation of ERP. These key success drivers are general regions which most of the projects of implementation based on ERP need to accomplish (Nike biz 2012). As an important component of the project, SAP ERP, the company of Nike decided that it should implement the solution of SAP AFS as a variant of software named as SAP R/3 particularly for the industry of apparel and footwear. With the strategy of single instance within the conformity, the SAP AFS application was used by Nike throughout geographic locations and also made choices of implementing various applications of SAP inclusive of management of the supply chain along with warehouse of data in business. It was realized by Nike, after the debacle that the supply chain management implementation using the ERP system software cannot and should not be lightly considered (Nike Inc 2012). The organization was able to feel this from the perspective of a third party taking over the point of view of the integrator that helped the company also in understanding the implementation flaws to which the company was exposed. Therefore, the lessons learnt from this perspective are many but the main focus of the lesson is on considering the important factors of success and management of change when implementing a complicated system of ERP. The Nike case study clearly illustrates the success story of the company after it failed but not all organizations can result in a positive consequence.

References

Amoako-Gympah, K., 2010, Perceived usefulness, user involvement and behavioral intention: an empirical study of Enterprise Systems implementation, Computer in Human Behavior, Vol. 41, pp. 731-745

Koch, C., 2004, Nike Rebounds: How (and Why) Nike Recovered from Its Supply Chain Disaster.

Kalin, S., 2002, The ROI of Application Integration.

Laudon, J., Laudon, K., 2010, A New Supply Chain Project Has Nike Running for Its Life. In Essentials of Management Information Systems: Managing the digital firm: sixth edition Pearson Education, ch.1- Additional Cases, Retrieved November 15, 2012.

McLaren, T., Head, M., Yuan, Y., 2005, Costs and benefits in Supply Chain Collaboration.

Laudon, KC., 2007, Management Information Systems: Managing the Digital Firm,10th edition, Pearson-prentice Hall.

McVey, S., 2001, Nike Blames i2 For Finish In Losers Bracket. Technology Evaluation Centers, Retrieved November 15, 2012.

Nike biz, 2012, Retrieved November 15, 2012.

Nike Inc, 2012, Retrieved November 15, 2012.

Nah, F.F., and Lau, J. L., Kuang, J., 2011, Critical factors of successful implementation of enterprise systems, Business Process Management Journal, Vol. 7 Issue 3, pp 285-297.

To export a reference to this article please select a referencing stye below:

My Assignment Help. (2016). Reasons For ERP Implementation Failure And Supply Chain Problems In Nike Case Study. Retrieved from https://myassignmenthelp.com/free-samples/nike-case-study-analysis-erp-system-failure.

"Reasons For ERP Implementation Failure And Supply Chain Problems In Nike Case Study." My Assignment Help, 2016, https://myassignmenthelp.com/free-samples/nike-case-study-analysis-erp-system-failure.

My Assignment Help (2016) Reasons For ERP Implementation Failure And Supply Chain Problems In Nike Case Study [Online]. Available from: https://myassignmenthelp.com/free-samples/nike-case-study-analysis-erp-system-failure

[Accessed 19 August 2024].

My Assignment Help. 'Reasons For ERP Implementation Failure And Supply Chain Problems In Nike Case Study' (My Assignment Help, 2016) <https://myassignmenthelp.com/free-samples/nike-case-study-analysis-erp-system-failure> accessed 19 August 2024.

My Assignment Help. Reasons For ERP Implementation Failure And Supply Chain Problems In Nike Case Study [Internet]. My Assignment Help. 2016 [cited 19 August 2024]. Available from: https://myassignmenthelp.com/free-samples/nike-case-study-analysis-erp-system-failure.